|

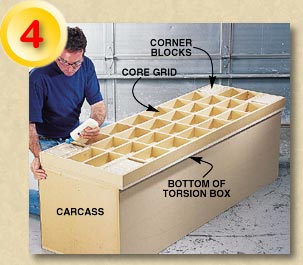

THE TORSION BOX The torsion box is designed to resist twisting. It consists of a web core made up of MDF strips notched for easy assembly (Fig. A). To ensure each piece is notched the same, gang cut the notches on the tablesaw (Photo 3). Glue and screw the sides (T2) and ends (T3) first to create a frame. Assemble the core grid (T4 and T5) inside the frame along with the corner blocks (T6) (Photo 4). Place the torsion top (T1) over the core grid and tack it in place. Be sure all the edges are flush (Photo 5). Then weight the top for clamping pressure (Photo 6). Once the glue has set, remove the weights, flip over the torsion box assembly and glue on the bottom (T1). With the torsion box complete, add the casters and the levelers (T7). The carcass is then screwed down onto the torsion box (Fig. A). BUILDING

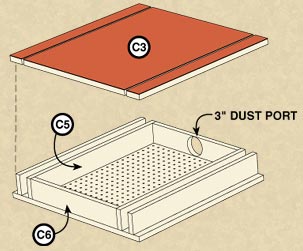

THE BOXES Cut the 3/8-in. T-slots in the top with a dado blade on your tablesaw. Attach the fixed boxes to the top and be sure to keep all the edges flush (Fig. A). DOWNDRAFT

BOX Drill a 3-in. hole into the center of one filler piece for a dust collector fitting. Perf-board makes a great template for drilling the 1/4-in. holes in the top. Use a countersink to widen the opening of each hole. ROUTER

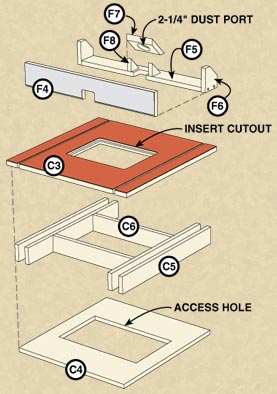

TABLE BOX The router is mounted onto a table insert that sits flush to the top. This allows you to lift the entire router out of the table for changing bits. Make two 8 in. by 16-in. access holes, one in the bottom of the router table and the other in the top of the carcass. These holes allow room for a pair of hands to adjust the router. TOOL BASES Thatís it. Youíre done! Now your shop will seem two sizes larger without moving a single wall! |

|

|

|

|

|

Ultimate

Tool Stand - Exploded

View & Electrical Connections -

Building

the Ultimate Tool Stand - Building

the Ultimate Tool Stand (continued) -

Special

Features - Special

Features (continued) -

Cutting

List & Shopping List