| topics |

| back to shop |

| home |

| |

| shop: corner-clamping fixture |

||

|

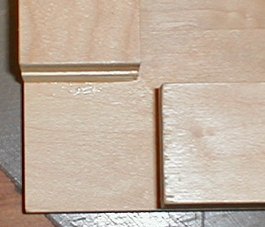

While this is neither an original nor a unique idea, it is a great solution. Besides cutting down on the number of required clamps, it reduces the need for diagonal measurements, saves time and vitually guarantees perfect 90deg corners.  Construction notes: As you can see from the following picture, construction is pretty simple. It has a base of very flat plywood. Two fences, fixed permanently to the base at a perfect right angle, provided the clamping reference. I used a scrap of baltic birch plywood, because it is typically higher grade than construction grade plywood - and having a very flat surface is paramount to building a useful fixture. Other scraps of the same plywood were used as the sides. If you will only use the fixture for short items, such as picture frames, a single 3/4" piece for the fence would be adequate. I made mine 1.5" high, to give me more freedom in placement of the clamps. Using my best reference square, I glued and clamped the fences in place and drove a handful of countersunk screws into the fences from below.  Details:

Finishing: To minimize any deflection of the fixture due to moisture changes, I sealed the entire fixture with a coat of shellac. Afterwards, a coat of wax on all the fixture surfaces will help prevent glue from sticking to the fences or base. |